JOBO CPE2 Plus Thermostat Upgrade

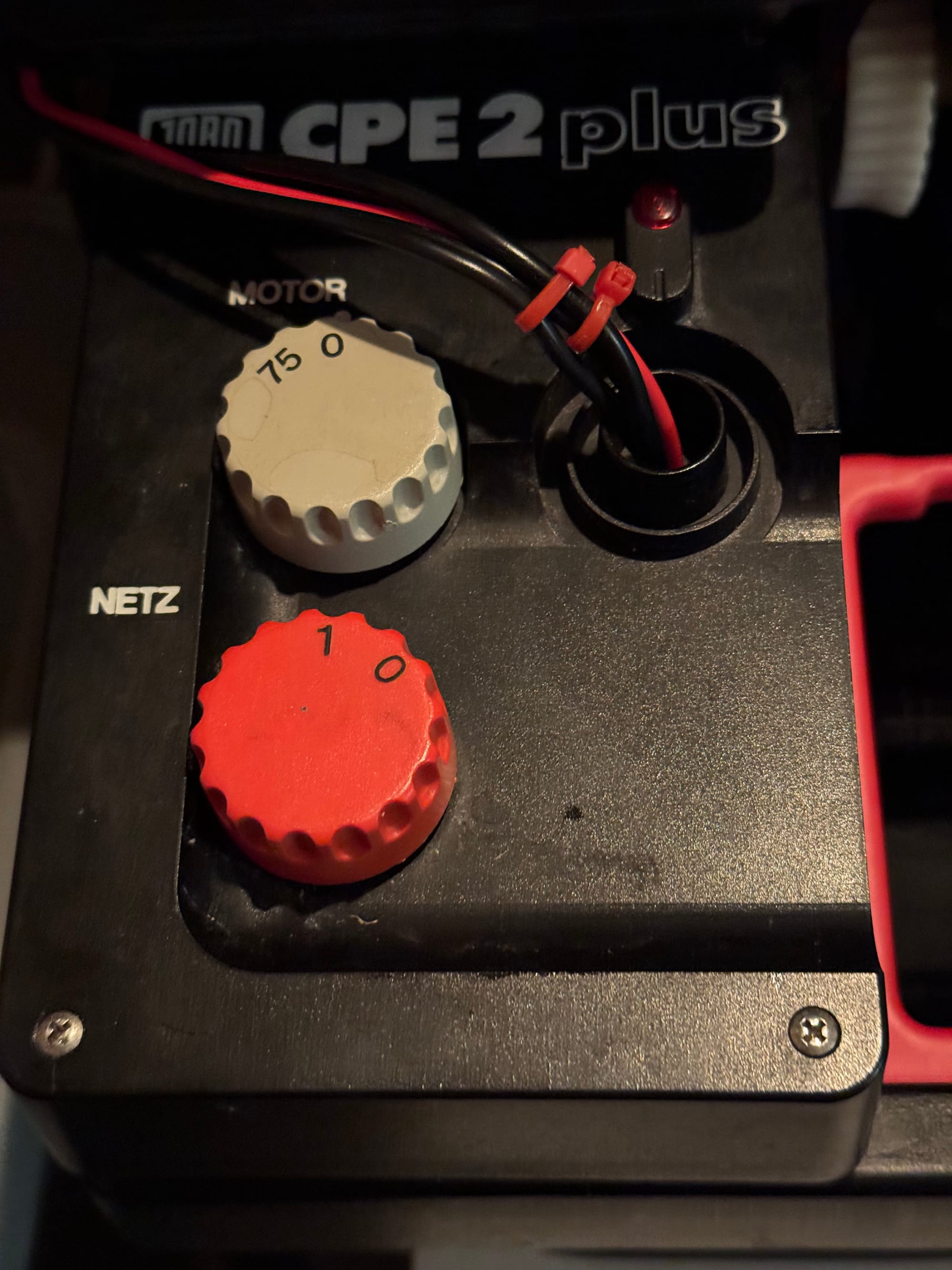

The JOBO CPE-2 Plus Processor is a cornerstone tool for darkroom enthusiasts and film photographers seeking to develop and process film or paper in a controlled environment. Designed to streamline the complexities of traditional film development, it provides consistent control over three critical variables: time, temperature, and agitation. My recent upgrade—replacing the mechanical thermostat with a STC-1000 Digital Temperature Controller—takes its capabilities to a new level, enhancing precision and usability for more consistent results.

The JOBO CPE-2 Plus Processor: A Technical Overview

The JOBO CPE-2 Plus Processor is an economical yet powerful system for developing both black-and-white and color film. Its design addresses the three key variables that affect development quality:

Time

While the CPE-2 Plus does not automate timing for filling or draining chemicals, it enables users to control timing manually. With the optional Lift accessory, this process is simplified, as it facilitates easy filling and draining of chemical solutions. Users must rely on an external timer, such as a wristwatch or darkroom timer, to ensure accurate intervals for each step.

Temperature

The CPE-2 Plus uses a water bath to temper chemicals and the processing tank or drum. This feature is especially crucial for color film, where precise temperature control is mandatory. Unlike black-and-white film, which allows for adjustments to development time to compensate for temperature variations, color film processing has no such uniform correction formula. A stable, accurate temperature is essential for consistent results.

Agitation

The processor employs a bi-directional rotation system to agitate the solutions. This unique feature prevents flow patterns that could lead to uneven development. Agitation is critical because it influences contrast and consistency. The rotary processing of the CPE-2 Plus increases agitation, which can reduce development times without sacrificing quality. This also enhances control over contrast, a key factor in achieving desired results.

The Need for a Thermostat Upgrade

The original mechanical thermostat in the JOBO CPE-2 Plus, when it was functional, was limited in precision at best. I'd never been able to rely on the knob, and there are no reasonable way to calibrate it.

With temperature being a critical factor—especially for color film—an upgrade to a STC-1000 Digital Temperature Controller enhances the system significantly. This digital thermostat provides:

- Precise Temperature Control: Maintains accurate temperatures within ±0.1°C, ideal for color and black-and-white film processing.

- Dual Relays: Controls heating and cooling, offering flexibility in maintaining consistent water bath temperatures. I don't have a cooler, so this will not be used.

- Digital Display: A bright LED screen shows real-time temperature readings and settings, making adjustments easier and more intuitive.

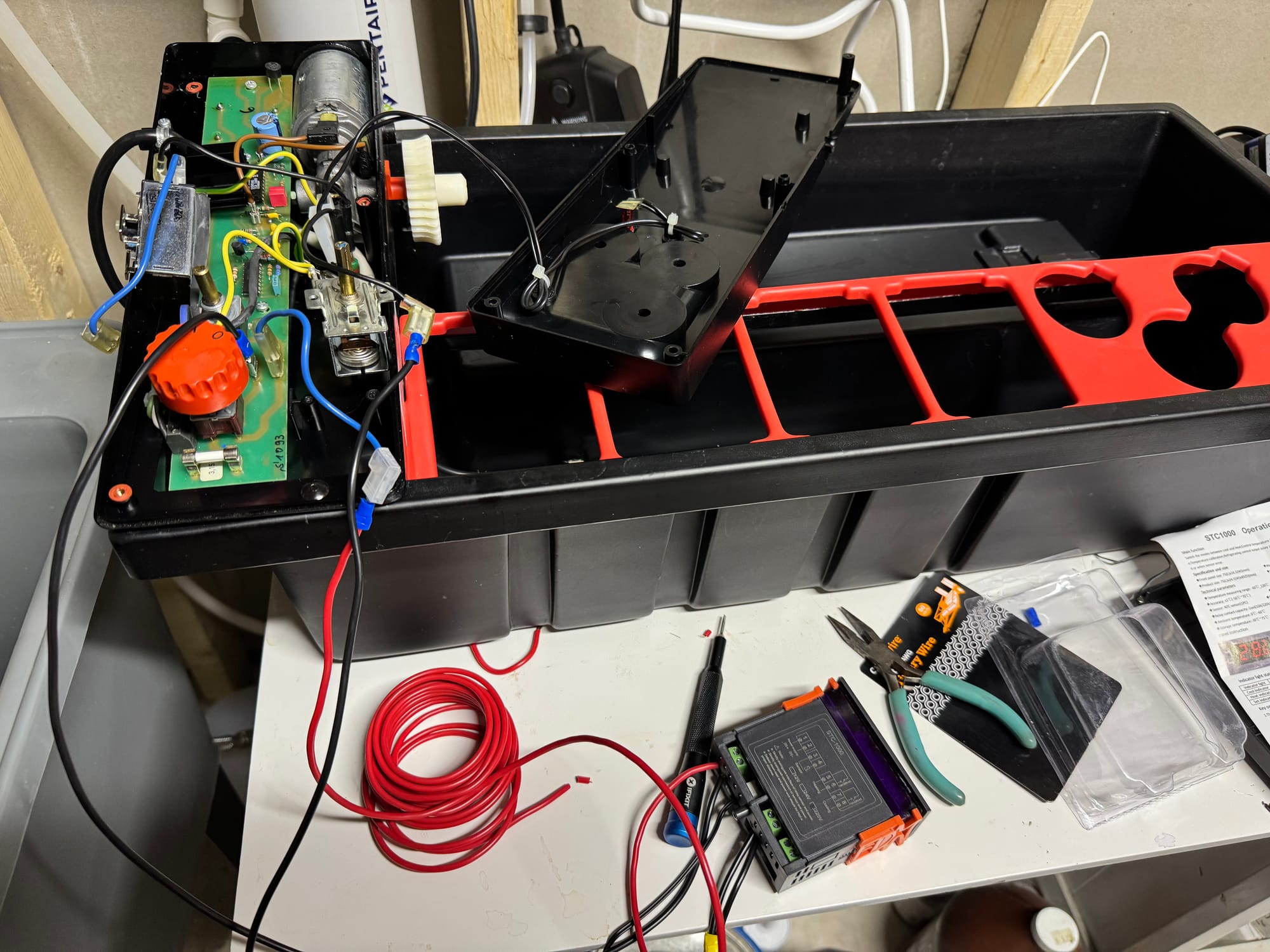

Upgrade Process: Replacing the Thermostat with the STC-1000

Here’s how I replaced the original thermostat with the STC-1000 Digital Temperature Controller:

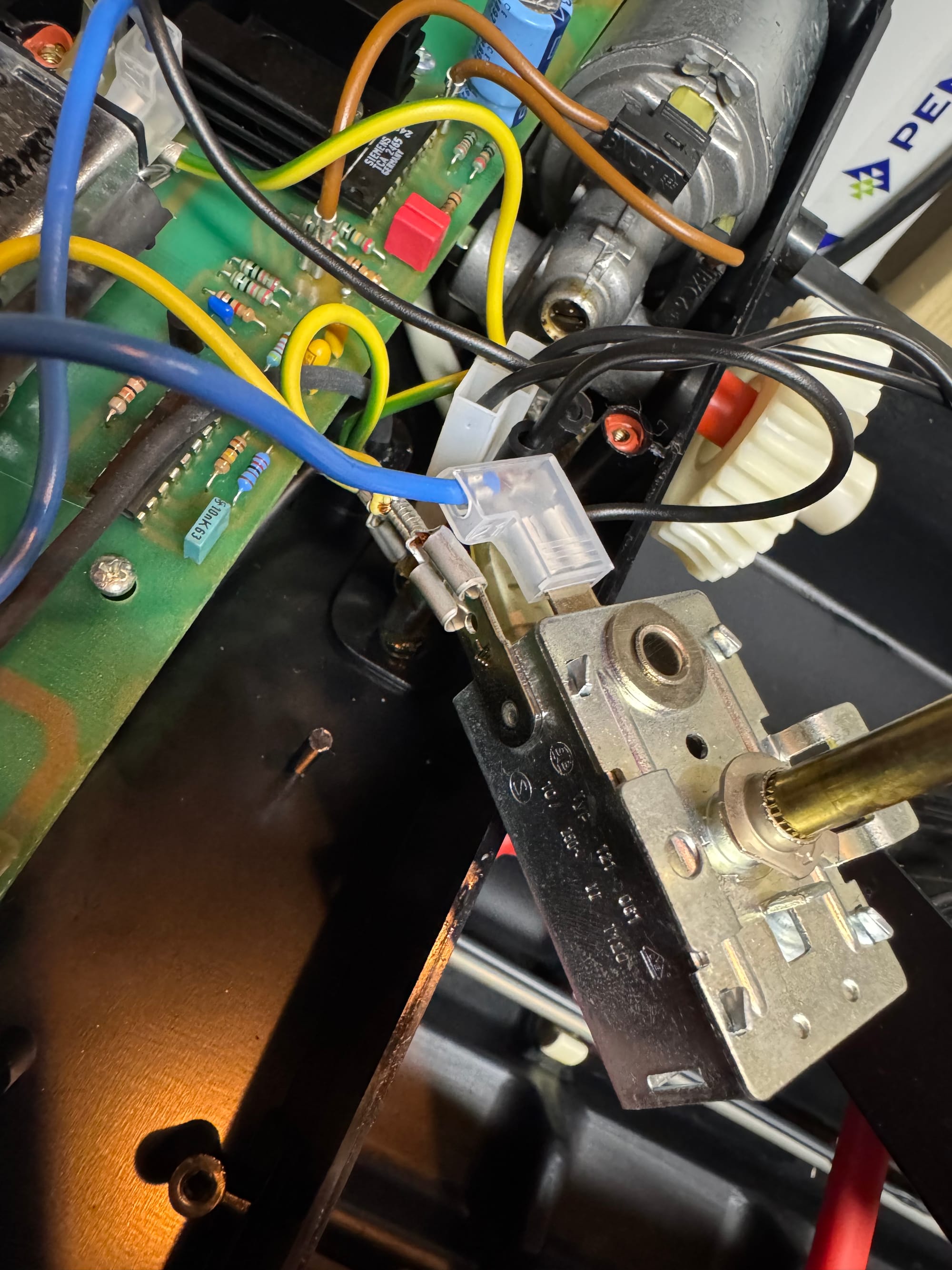

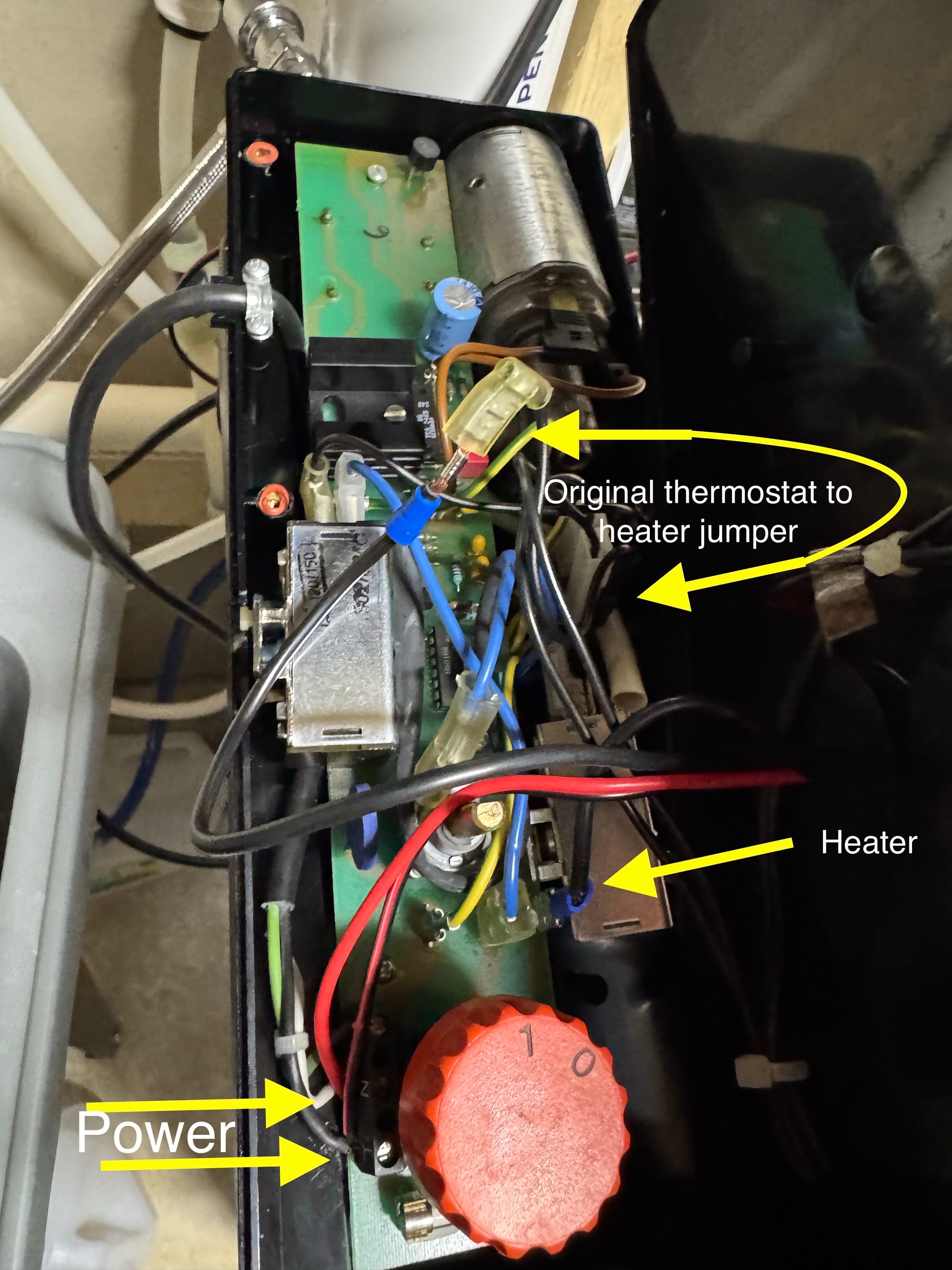

- Bypassing the Mechanical Thermostat

The original thermostat was disconnected, and the STC-1000 was wired directly to the JOBO’s heating element and power supply. This ensures that the digital thermostat exclusively controls the heating system. This also maintains the factory overheating safety, and indicator light.

- Installing the NTC Sensor Probe

The STC-1000 comes with an NTC (Negative Temperature Coefficient) sensor probe, which I placed inside the JOBO’s water bath. Proper placement ensures accurate readings, and I secured the probe to keep it submerged without obstructing the drum rotation. This can also be used to check temperature of chemistry within individual bottles.

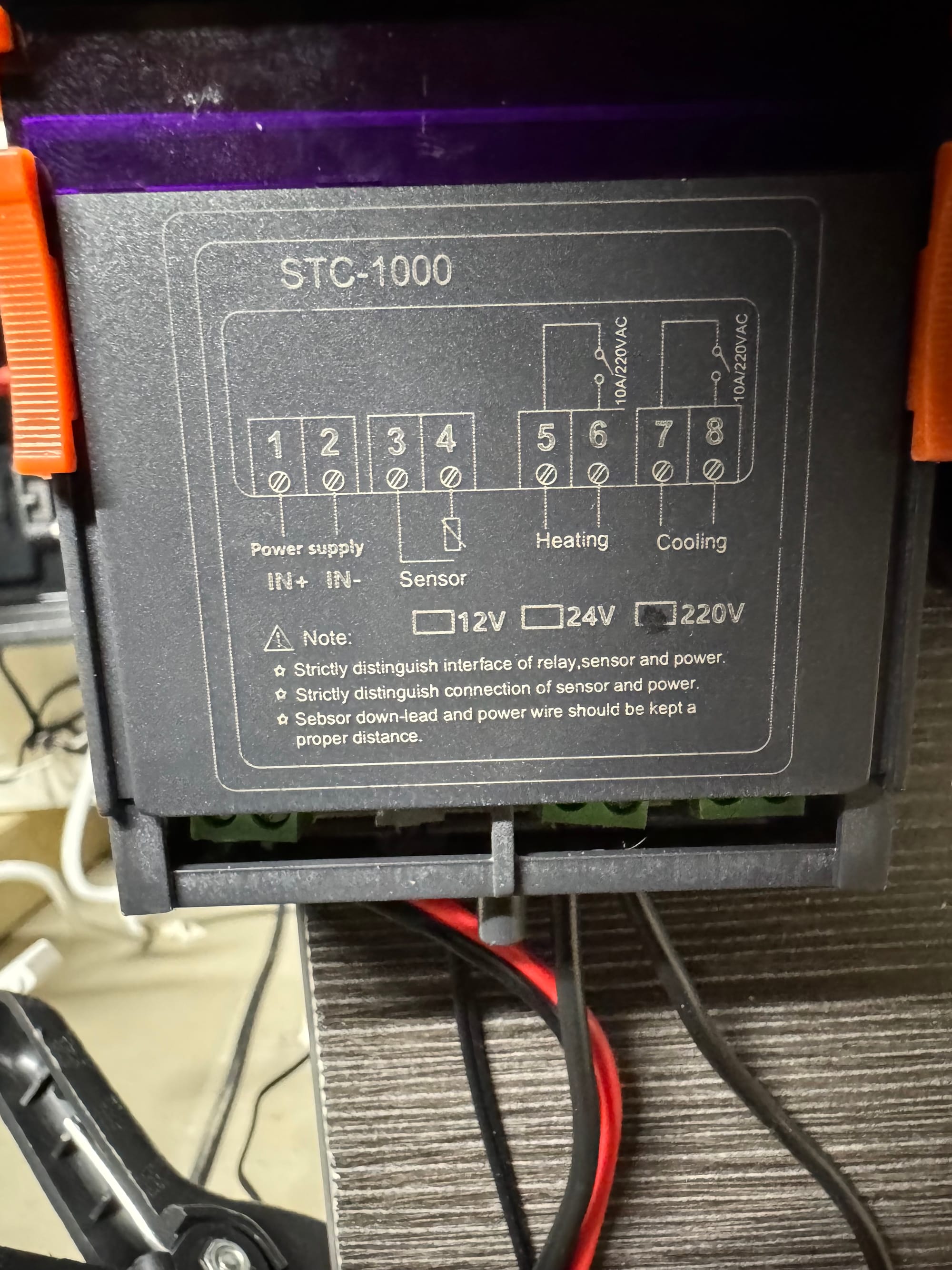

- Wiring the STC-1000

Using the provided wiring diagram, I connected the heating relay to the JOBO’s heater and the cooling relay (optional) to an auxiliary cooling system. I don't have a cooler, so this isn't wired up..

- Configuring the Controller

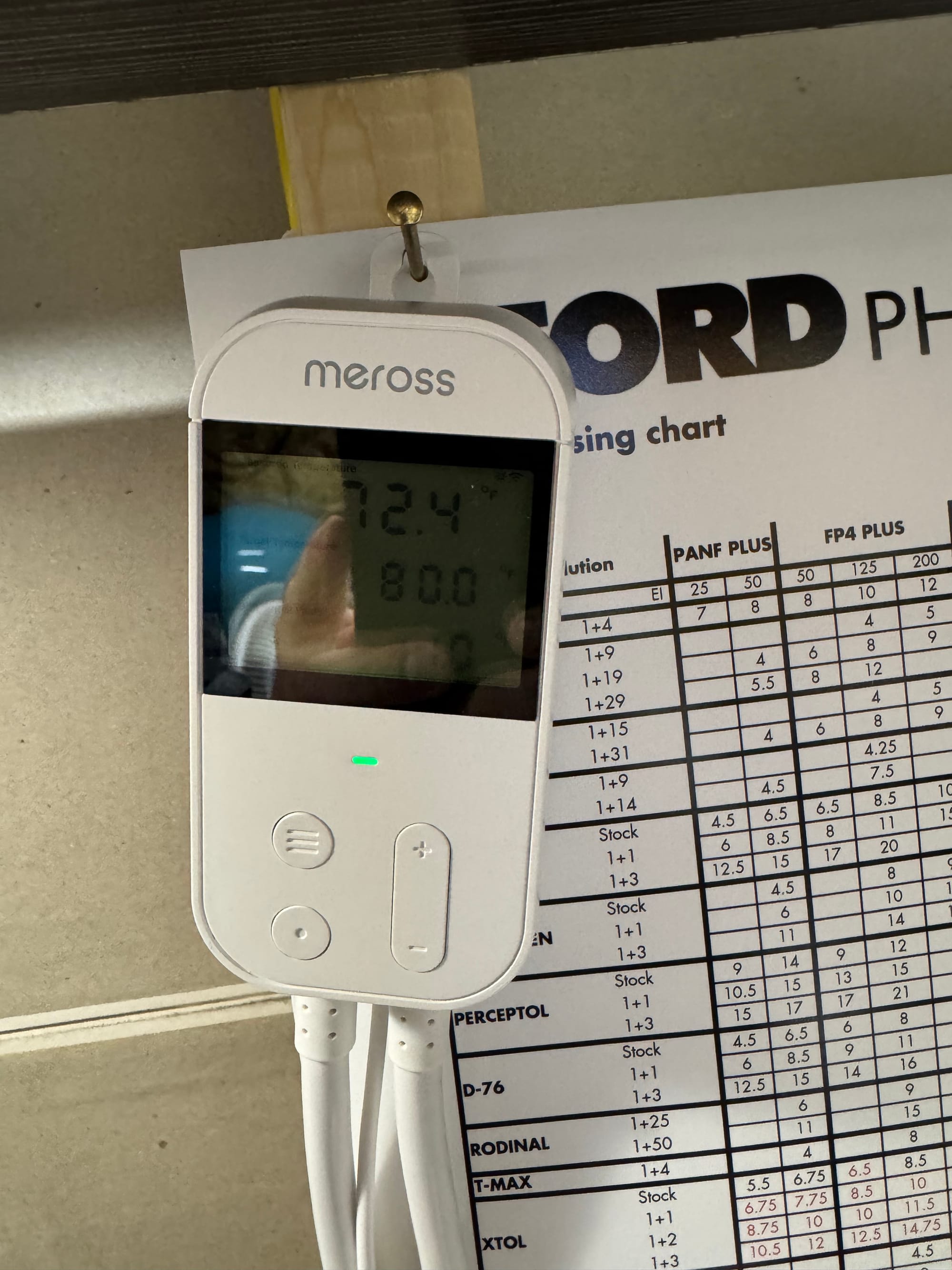

I programmed the STC-1000 for a target temperature of 27°C (80°F) with a hysteresis of ±0.3°C, within range of my Ilford DDX & Cinetech C-41 color film Chemistry.

- Testing and Calibration:

After completing the installation, I tested the system by running a series of water bath cycles. The STC-1000 performed flawlessly, maintaining the desired temperature range consistently and efficiently.

Results and Benefits of the Upgrade

The upgrade has transformed my JOBO CPE-2 Plus into an even more reliable and precise processing system. Here are the key improvements:

- Enhanced Temperature Accuracy: The STC-1000 provides superior control, ensuring consistent development results across batches.

- User-Friendly Design: The digital interface is a significant upgrade from the original thermostat, offering a clear display and easy adjustments.

- Improved Flexibility: The dual-relay design supports future enhancements, such as integrating cooling systems for additional stability in warm environments.

For both black-and-white and color film processing, this upgrade has increased my confidence in achieving professional-quality results every time.

Smarts

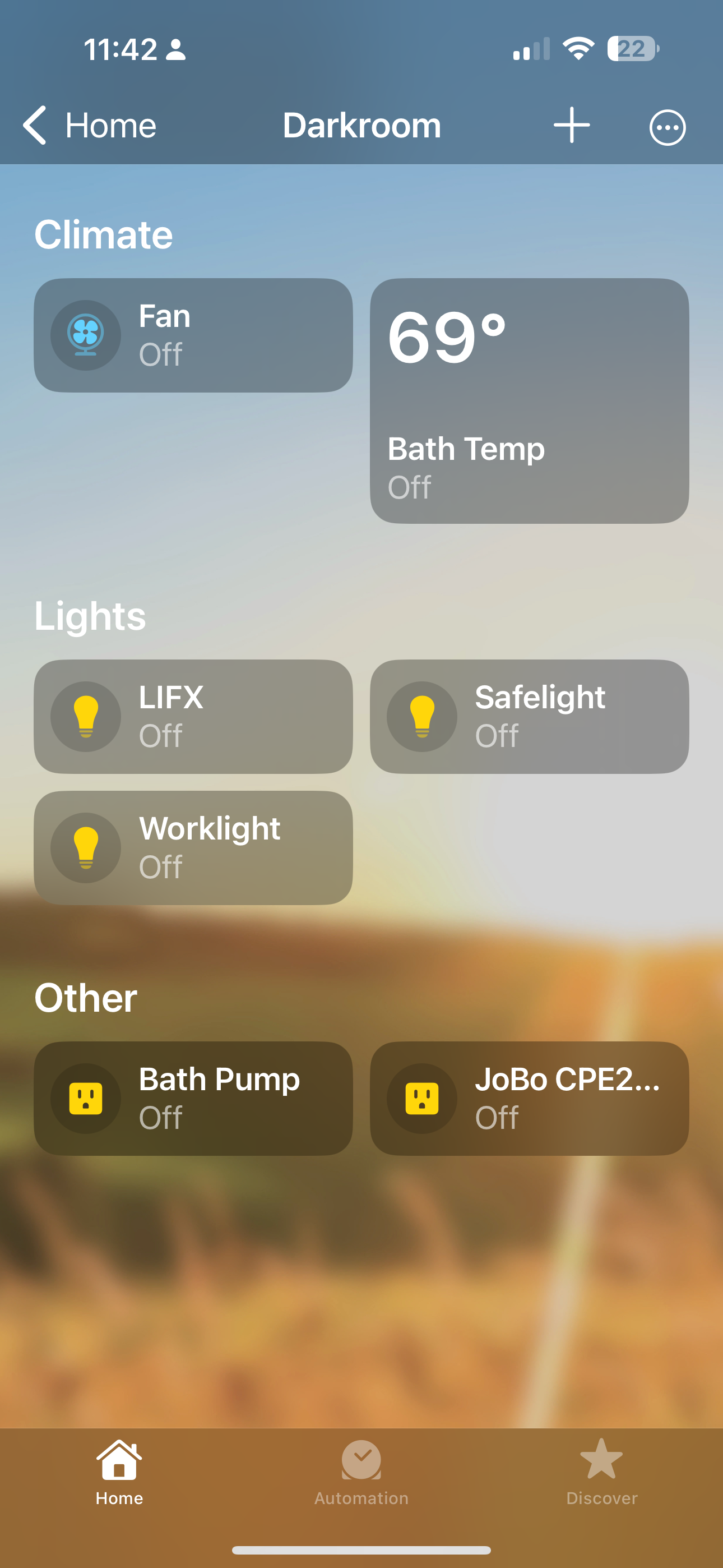

- Smart Switch Integration

- Connected the JOBO, water circulation pump, safelights, a fan, and work lights to a couple Meross smart switches for centralized control in Apple HomeKit.

- Remote Management

- I am now able to preheat the JOBO water bath, start the pump, turn on the fan, or adjust lighting, as well as monitor water bath temperature remotely.